Dehulling method of corn complete equipment

Dehulling method of corn complete equipment

There are two commonly used dehulling methods for corn complete equipment: dry dehulling and wet dehulling.

1: Dry peeling means that after the corn is cleaned.

It directly enters the peeling equipment for peeling without going through the water vapor conditioning process. This method is suitable for high-moisture corn.

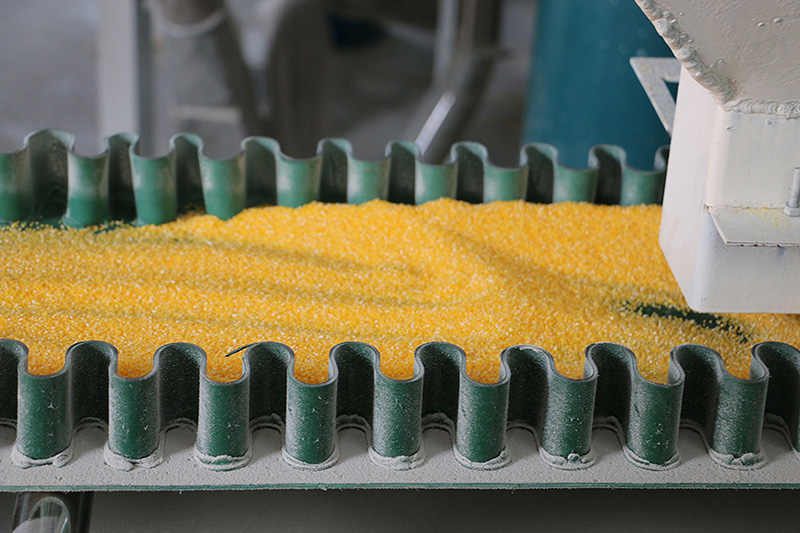

The dry process is a kind of corn processing. Dry processing is also called dry grinding. It produces corn products with different thicknesses by cleaning, peeling and degerming, screening, crushing, and grading the raw corn grains.

Compared with the wet process, the dry process has the following particularities:

Equipment specialization: When using the dry process to produce corn products, the equipment used involves special equipment such as degerminators and embryo extractors. Due to the use of these special equipment, the quality and yield of products processed by corn processing machinery are very high. . For example, the extraction rate of corn germ can reach 8%~12%, the fat content of germ is 18%~22%, and the fat content of corn grits is below 0.9%.

Dry corn processing machinery continuously develops and utilizes corn products, and corn and corn products have become the staple food in people's lives and important raw materials for various industries. Dry processing can mainly obtain three products of different particle sizes: corn grits, corn flour and sub-peel powder. Corn grits and corn flour can be used as food raw materials. They are rich in nutrients and are deeply loved by consumers. Meal can be used as feed for raising poultry and livestock

2. Wet peeling refers to corn peeling after cleaning and water vapor conditioning.

This method is commonly used in corn processing, especially when processing low-moisture corn. Wet peeling must be used, otherwise it will seriously affect the peeling efficiency and efficiency of corn processing machinery. Embryo extraction rate.

In addition, in order to achieve the best peeling effect, in the corn processing process, the raw grain needs to be moistened with water to change the physical structure of the corn seed to make the epidermis tough and not easy to break, making peeling easier and more conducive to processing. . When the moisture content of corn is too low, peeling is more difficult and the quality of the skin is poor. When the moisture content in the corn is too high, it will also affect the effect of peeling, and even cause blockage of equipment parts, affecting the effect of processing and reducing the efficiency of processing.