Technological Process of Rice Processing

Technological Process of Rice Processing

Our company has been focusing on the development of rice processing equipment projects for many years. Lead the excellent team to develop with many enterprises. Next, the rice processing equipment will introduce the rice processing process to you.

In view of the whitening and polishing effect of various rice mills and polishing machines commonly used in China, only one or two rollers are needed to whiten the rice of standard 1 and standard 2; If processing clean rice (also known as no panning rice, pearl rice, crystal rice, etc.) and other high-precision grade rice, it is necessary to use three or even four rollers to whiten, and then multi roller polishing treatment to obtain. Although many rice processing enterprises are limited by production sites and plant buildings, their rice processing equipment usually adopts floor layout or platform layout, but their rice processing process is basically similar.

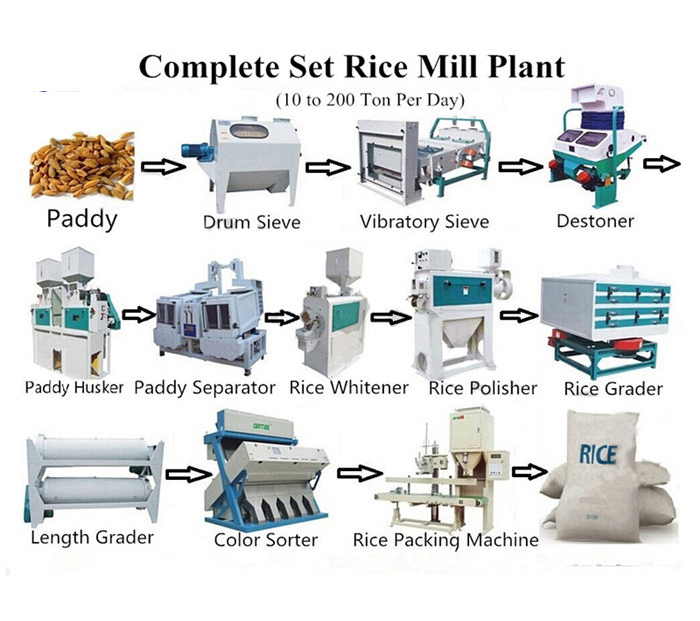

(1) Processing ordinary Precision Rice → cleaning → removing stone → hulling → separating coarse grain → milling → grading white rice → packaging → warehousing.

(2) Processing of high-precision grade rice → preliminary cleaning → cleaning → removing stone → hulling → coarse separation → brown rice cleaning (thickness classification) → multi-stage light milling → white rice classification → multi-stage polishing → white rice classification → self rice cleaning (length classification) → color separation and purification → packaging → warehousing.

The above is the rice processing equipment to introduce the rice processing process.