30 Tons to 80 Tons Per Day Rice Machinery

Brand Golden Grain

Product origin China

Delivery time 15 Working Days

Supply capacity 100sets/month

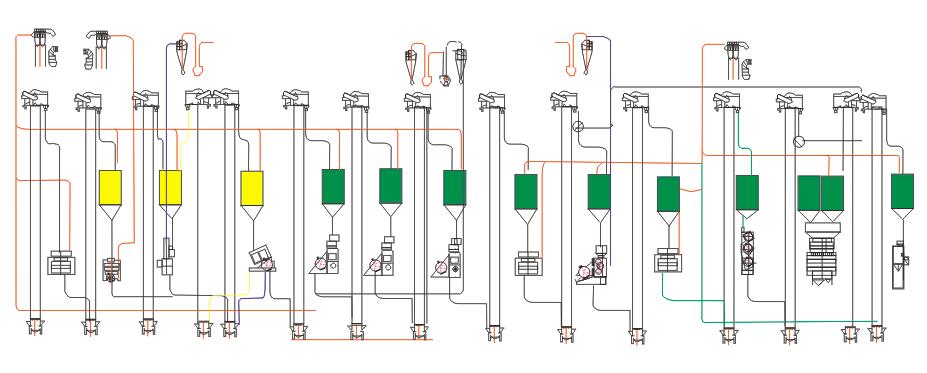

1.The rice production line includes the primary screen assembly, cleaning screen assembly, stone remover assembly, rice husker assembly, grain roughing screen assembly, rice machine component, white rice screen assembly, color separator component and rice polishing machine component.

2.The rice production line is respectively provided between the two adjacent components, Through the function of different components, under the function of the elevator, the complete processing process from rice to rice is completed.

3.The whole production line has compact structure, small floor area and convenient installation; At the same time, rice yield is large, efficiency is high and quality is high.

30Tons to 80 Tons Per Day Rice Processing Machine

Product introduction of rice processing equipment

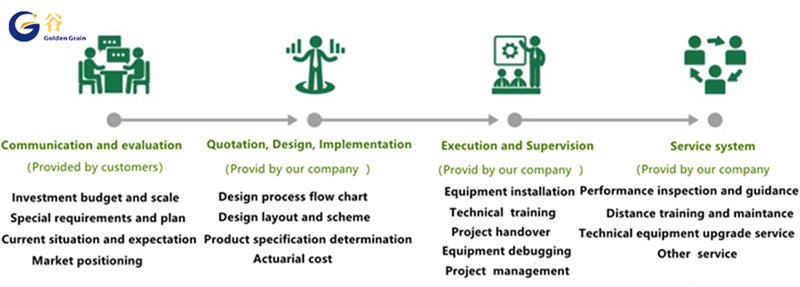

The rice mill plant of 30-80 tons per day (rice processing equipment)we designed are based on customers’ actual demand. We provide reasonable design scheme,technology training, careful installation etc.

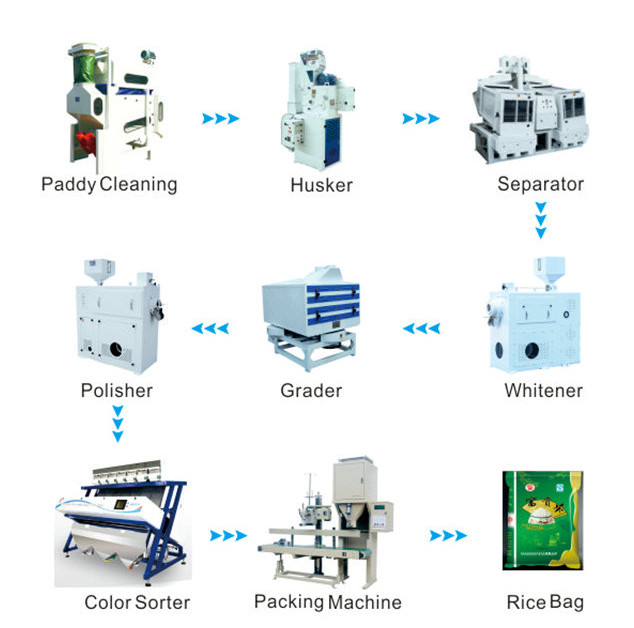

Here are Rice Milling Steps :

1. Pre-cleaning: removing all impurities and unfilled grains from the paddy.

2. De-stoning: separating small stones from the paddy.

3. Husking: removing the husk from the paddy.

4. Husk aspiration: separating the husk from the brown rice/unhusked paddy.

5. Paddy separation: separating the unhusked paddy from the brown rice.

6. Whitening: removing all or part of the bran layer and germ from the brown rice.

7. Polishing: improving the appearance of milled rice by removing remaining bran particles and by polishing the exterior of the milled kernel.

8. Sifting: separating small impurities or chips from the milled rice.

9. Length grading: separating small and large brokens from the head rice.

10. Blending: mix head rice with predetermined amount of brokens, as required by the customer.

11. Weighing and bagging: preparing milled rice for transport to the customer.

Product parameters or rice processing equipment(rice mill plant)

Product features and application or rice processing machine(rice processing machine)

The utility model provides a rice production line, belonging to the field of automatic processing equipment.

The rice mill plant includes the primary screen assembly, cleaning screen assembly, stone remover assembly, rice husker assembly, grain roughing screen assembly, rice machine component, white rice screen assembly, color separator component and rice polishing machine component.

The rice mill plant is respectively provided between the two adjacent components, Through the function of different components, under the function of the elevator, the complete processing process from rice to rice is completed.

The whole rice mill plant has compact structure, small floor area and convenient installation; At the same time, rice yield is large, efficiency is high and quality is high.

Our project case of rice processing equipment as follows:

30 Tons Per Day Rice Mill Plant(rice processing machine)

50 Tons Per Day Rice Processing Equipment

80Tons Per Day Rice Processing Machine

Packing&Delivery of rice mill plant

Packaging Details

1. We will pack all single machine of rice mill plant with the plastic film.

2.Fix the rice processing equipment on the container for the safety of long-time transportation of goods.

3.Some special unit of rice processing machine will be putted into the box to avoid any damage or missing.

4.Small parts of rice processing mahcine will be putted into the bags, boxes or make special packaging.

5. According to customer requirements, each product of rice mill plant is labeled with name and quantity.

Port:Dalian,China

Our cooperation with foreign clients

If you have any questions, welcome to contact us!

Company information

Liaoning Golden Grain Grain and Oil Machinery Co., Ltd(Formerly known as Zhengshuanghuan General Equipment Manufacturing Co.,Ltd)was established on August 30,1992 in Shenyang, China.

Our company has nearly 30 years professional experience in manufacturing Grain Machinery,the main products includes :Maize Milling Machine,Rice Milling Machine,Rice Processing equipment(Rice processing machine),Rice mill plant,Wheat Flour Milling Machine,Sorghum Milling Machine,Millet Milling Machine and Oil Refining Machine.

Factory covers an area of 20000 square meters, 6000squrare meters office building area,owns high quality standard heavy industrial production workshops.Employees includes medium and senior professional management personnel, engineering technical personnel and professional foreign trade team sales staff.

We design products according to customers’ specific requirements with carefully installation and technical training. Products have been exported to many countries such as:Russia,North Korea. Viet Nam, Nigeria, South Africa, and Southeast Asia. We are willing continue to expand our business around the world.