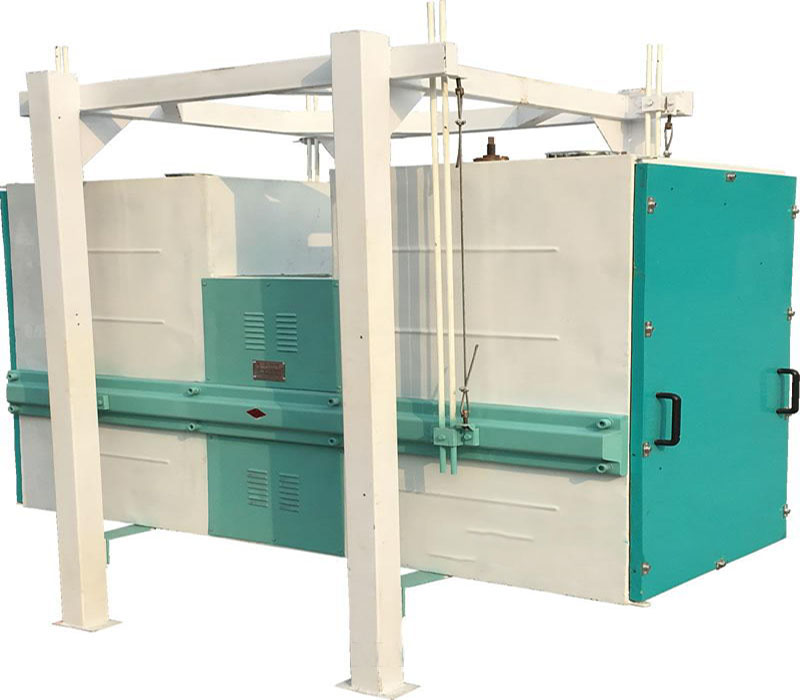

Double Bin Plansifter

Brand Golden Grain

Product origin China

Delivery time 3-7 Working Days

Supply capacity 100sets/month

1.flour mill plansifter has common type and closed type for users to choose.

2.flour mill plansifter closed type of double-bin plansifter has larger sieve area and better sealing performance.

3. Flour mill plansifter has wooden double-sided plastic screen grid, 6-12 grids are configured according to different screening requirements.

flour plansifter machine

flour plansifter machine introduction

flour plansifter machine is a new product which digests, absorbs and innovatively designs the same kind of prototype made by Buhler company of Switzerland.

flour plansifter machine is mainly used as the high-efficiency flour inspection screen of flour mill, and flour plansifter machine also used as the screening of ground powder.

flour plansifter machine can also be used in other powder screening and grading fields, such as corn mill, feed mill, chemical industry, pharmaceutical industry, etc.

Double bin flat screen is mainly suitable for medium and small grain processing plants, food, chemical, pharmaceutical, feed and other granular, powdery materials separation and screening. It has the advantages of large sieving area, beautiful appearance, convenient installation, etc. it is a very ideal screening equipment for granular materials.

flour mill plansifter Working Principle

flour shifter machine is mainly suitable for medium and small grain processing plants, food, chemical, pharmaceutical, feed and other granular, powdery materials separation and screening. flour shifter machine has the advantages of large sieving area, beautiful appearance, convenient installation, etc. it is a very ideal screening equipment for granular materials.

flour mill plansifter parameters

Type | Capacity(t/h) | Power(kw) | Spindle speed(r/min) | Rotary diameter of screen body(mm) | Packing height of sieve box | Weight (kg) | Dimension (mm) | |

Normal | Enclosed | |||||||

FSFJ2x10x63 | 2-2.5 | 1.1 | 260 | Ø50-55 | 900 | 550-580 | 1690x1270x1500 | |

FSFJ2x10x70 | 3-3.5 | 1.1 | 260 | Ø50-55 | 900 | 650-670 | 1840x1390x1760 | |

FSFJ2x10x83 | 5-8 | 1.5 | 260 | Ø50-55 | 1040 | 1120 | 730-1000 | 2386x1678x2250 |

FSFJ2x10x6100 | 8-12 | 2.2 | 260 | Ø50-55 | 1040 | 1120 | 1200-1600 | 2856x1811x2550 |

flour mill plansifter process

flour mill plansifter features and application

flour shifter machine compact design, high processing capacity

The flour shifter machine is equipped with two screen boxes;

flour shifter machine high processing capacity, light weight, it can be installed in space.

flour shifter machine modular design can be very good to adapt to customer needs

flour shifter machine modular design can adjust the processing capacity by changing the number of screen layers to meet the needs of customers;

flour shifter machine can be assembled with three different versions of the screen box, so flour shifter machine can meet the needs of a wide range of applications.

Packing&Delivery

Packaging Details

1. We will pack all single machine with the plastic film.

2.Fix the machine on the container for the safety of long-time transportation of goods.

3.Some special unit will be putted into the box to avoid any damage or missing.

4.Small parts will be putted into the bags, boxes or make special packaging.

5. According to customer requirements, each product is labeled with name and quantity.

Port:Dalian,China

Our cooperation with foreign clients

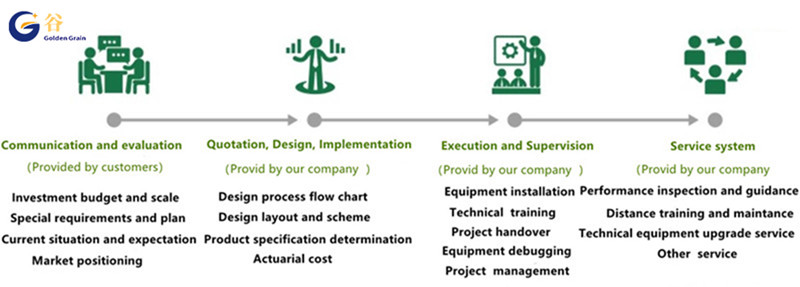

Company information

Liaoning Golden Grain Grain and Oil Machinery Co., Ltd(Formerly known as Zhengshuanghuan General Equipment Manufacturing Co.,Ltd)was established on August 30,1992 in Shenyang, China.

Our company has nearly 30 years professional experience in manufacturing Grain Machinery,the main products includes :Maize Milling Machine,Rice Milling Machine,Wheat Flour Milling Machine,Sorghum Milling Machine,Millet Milling Machine and Oil Refining Machine.

Factory covers an area of 20000 square meters, 6000squrare meters office building area,owns high quality standard heavy industrial production workshops.

Employees includes medium and senior professional management personnel, engineering technical personnel and professional foreign trade team sales staff.

We design products according to customers’ specific requirements with carefully installation and technical training. Products have been exported to many countries such as:Russia,North Korea. Viet Nam, Nigeria, South Africa, and Southeast Asia. We are willing continue to expand our business around the world.

Factory view

If you have any questions, welcome to contact us!