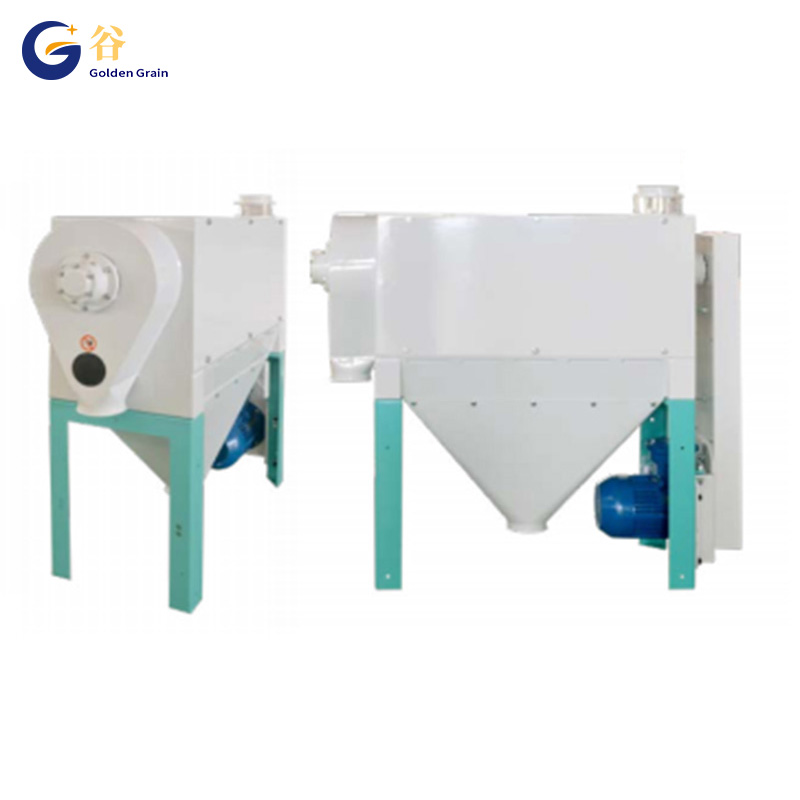

Wheat Brusher

Brand Golden Grain

Product origin China

Delivery time 3-7 Working Days

Supply capacity 100set/month

1. wheat brushing machine function: mainly used for cleaning, threshing and brushing of wheat.

2. The wheat brushing machine is a wheat brushing machine with good impurity removal effect.

3. Multiple special-shaped beating plates form a spiral shape on the main shaft, and the brushing force is strong.

Wheat Brush Machine

wheat brushing machinedescription of wheat brushing machine

Wheat Brush Machineis mainly used in the flour mill to clean up the residual ash on the surface of wheat, brush off the cracked epidermis and wheat germ, and brush off the bran, fine ash and bacteria on the epidermis of wheat. Because the machine adopts a cylinder (360 degree sieve cylinder).

Wheat Brush Machine is a horizontal spiral brushing machine, which is mainly composed of organic shell, rotor, brush plate, sieve cylinder and transmission.

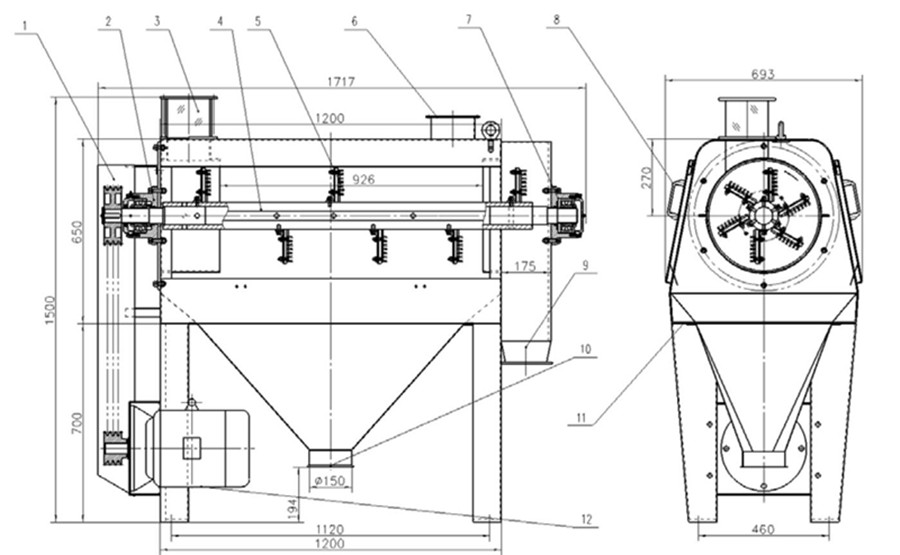

(1) grain cleaning equipment casing is mainly made of 4 mm steel plate bent and welded. The top of the casing has a feeding port and a suction port. There is a discharge port at the tail, and a ash outlet at the lower part. The left and right sides of the casing have doors. Open the door and fold the screen.

(2) The rotor is mainly composed of a main shaft and a brush plate. The spindle is provided with an adjustable angle brush plate supported by the left and right bearings on the casing. During Wheat Brush Machine operation, the rotor rotates at a high speed in the cavity formed by the screen cylinder.

(3)grain cleaning equipment transmission device is at the feeding end of the machine, and the transmission system is mainly composed of a motor, a V-belt pulley and a V-belt. The motor is mounted on the adjustable bracket, and the V-belt is tightened by adjusting the bracket to ensure the stability of the rotor speed and extend the service life of the V-belt. The transmission part is provided with a protective cover.

Working principles of wheat brushing machine

grain cleaning equipment material is fed from the feed port to allow the material to enter the brushing zone.

The brush plate on the rotor rotating at high speed strongly rubs the wheat to achieve separation of the material.

At the same time, grain cleaning equipment brush plate on the rotor pushes the wheat to the outlet end while wiping the wheat.

grain cleaning equipment separated dust forms the undersize, and the undersize is discharged from the bottom ash outlet.

Product Parameters of wheat brushing machine

| Type | Specification of screen cylinder | Distance between brush and screen cylinder (mm) | principal axis speed rpm | Power Kw | Yield t/h | Wheight Kg | Overall dimension L x Wx H | |

| diameter mm | length mm | |||||||

| FSMJ 40X1 | 400 | 975 | ≥15 | 840 | 7.5 | 3.5~8.5 | 500 | 1720X 693X1 500 |

| FSMJ 2X 40X 100 | 400 | 975 | ≥15 | 840 | 7.5X2 | 7~17 | 990 | 1720X 1165X 1500 |

| FSMJ 2X40X 120 | 400 | 1175 | >15 | 840 | 7.5X2 | 10~20 | 1100 | 1920X 1165X 1500 |

Product feature and application of wheat of brushing machine

The grain cleaning equipment has high screening efficiency and is an ideal wheat skin treatment equipment for flour mills.grain cleaning equipment is newly developed by our compamy .It has the function of brushing and milling and the features of high flour yield and good flour quality.

wheat brush machine Shield 2.wheat brush machine front bearing boday 3.wheat brush machine feed port 4.wheat brush machine shaft 5.wheat brush machine scraper 6.wheat brush machine suction outlet.7 wheat brush machine rear bearing body 8.wheat brush machine observation gate 9.wheat brush machine discharge port 10.wheat brush machine ash outlet 11.wheat brush machine casing 12.Motor

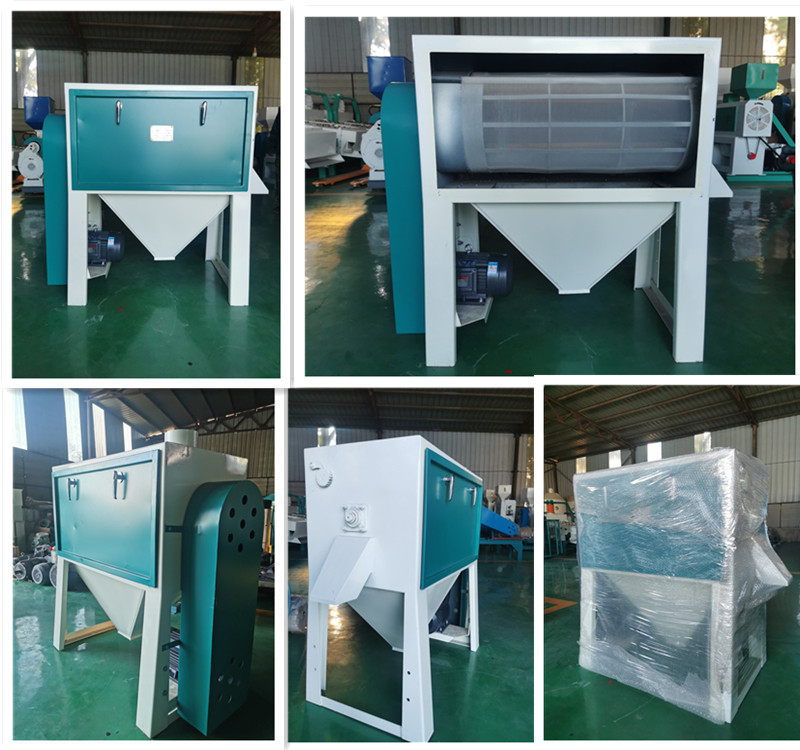

Packaging Details

1. We will pack all single machine with the plastic film.

2.Fix the machine on the container for the safety of long-time transportation of goods.

3.Some special unit will be putted into the box to avoid any damage or missing.

4.Small parts will be putted into the bags, boxes or make special packaging.

5. According to customer requirements, each product is labeled with name and quantity.

Port:Dalian, China

Our cooperation with foreign clients

Company information

Liaoning Golden Grain Grain and Oil Machinery Co., Ltd(Formerly known as Zhengshuanghuan General Equipment Manufacturing Co.,Ltd)was established on August 30,1992 in Shenyang, China.

Our company has nearly 30 years professional experience in manufacturing Grain Machinery,the main products includes :Maize Milling Machine,Rice Milling Machine,Wheat Flour Milling Machine,Sorghum Milling Machine,Millet Milling Machine and Oil Refining Machine.

Factory covers an area of 20000 square meters, 6000squrare meters office building area,owns high quality standard heavy industrial production workshops.Employees includes medium and senior professional management personnel, engineering technical personnel and professional foreign trade team sales staff.

We design products according to customers’ specific requirements with carefully installation and technical training. Products have been exported to many countries such as:Russia,North Korea. Viet Nam, Nigeria, South Africa, and Southeast Asia. We are willing continue to expand our business around the world.

Factory view

If you have any questions, welcome to contact us!